“How might we design the next generation fiber cup to be recoverable on a global scale, while maintaining the performance standards we know and trust?”

– challenge by OpenIDEO

GoodCup is a holistic solution to build sustainable consumer habits through a deposit system, disposable cups and a reusable cup producer partnerships.

Self-initiated project by design for human nature

by the team of design for human nature

2018

Project during my internship semester.

Background

“The fiber cup is everywhere. In 2016, 250 billion were distributed globally, and it’s estimated that number will increase to 266 billion by 2022. While convenient for enjoying a hot coffee or cold beverage on the go, too many fiber cups end up in landfills, contributing to greenhouse gas emissions and wasting valuable resources.

There are two core issues with fiber cups: how they’re made and how the materials they’re made of are valued. Most fiber cups have a plastic liner to prevent leaks. The fiber and plastic are recyclable once separated, but limitations and inconsistencies in recycling infrastructure around the world mean that in most markets these materials aren’t easily recovered. While recycled fiber and plastic are valuable, what’s currently recoverable from cups doesn’t sell for much, so there’s no strong incentive for recyclers to recover the materials.”

The system

Who will benefit?

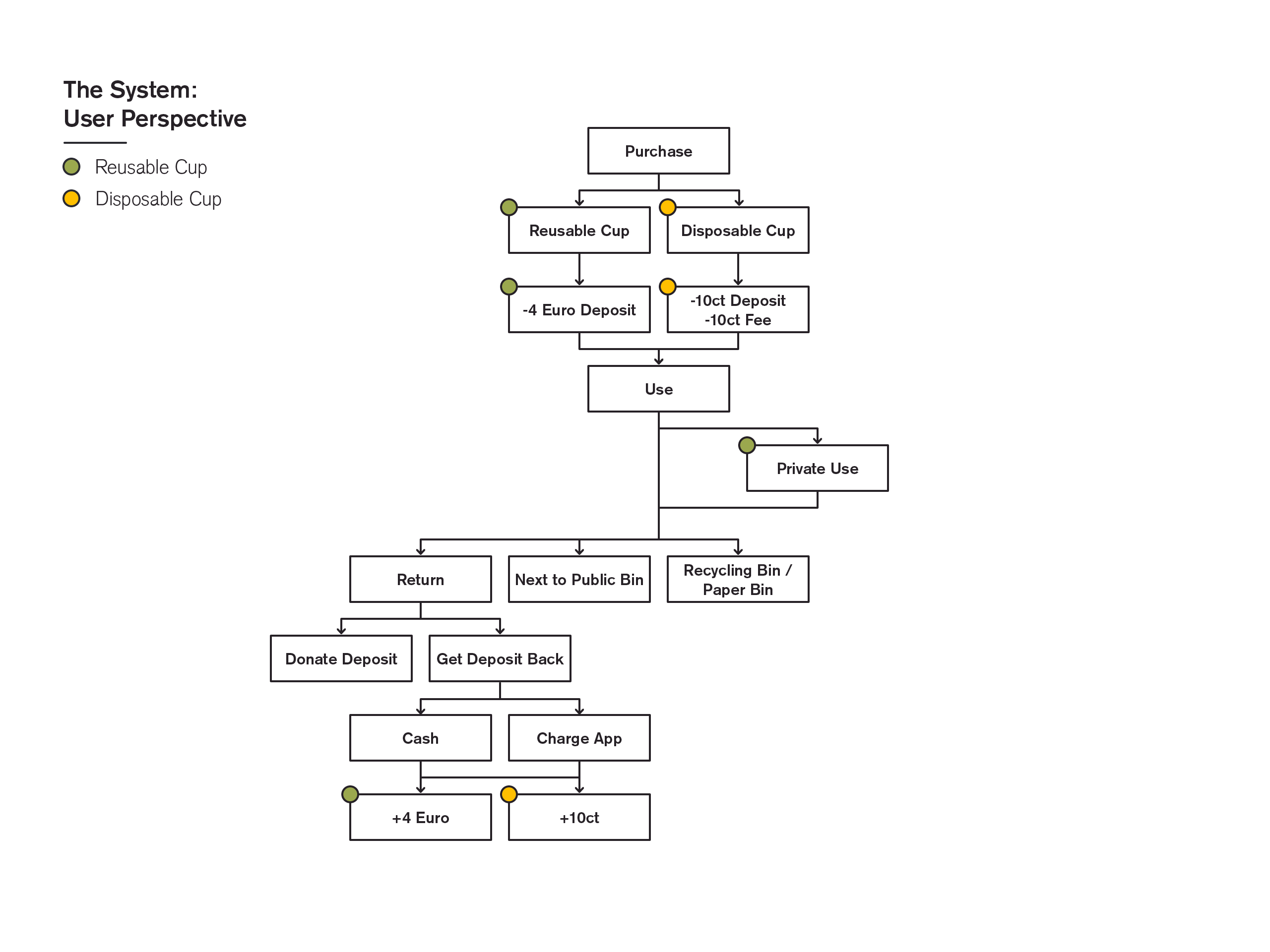

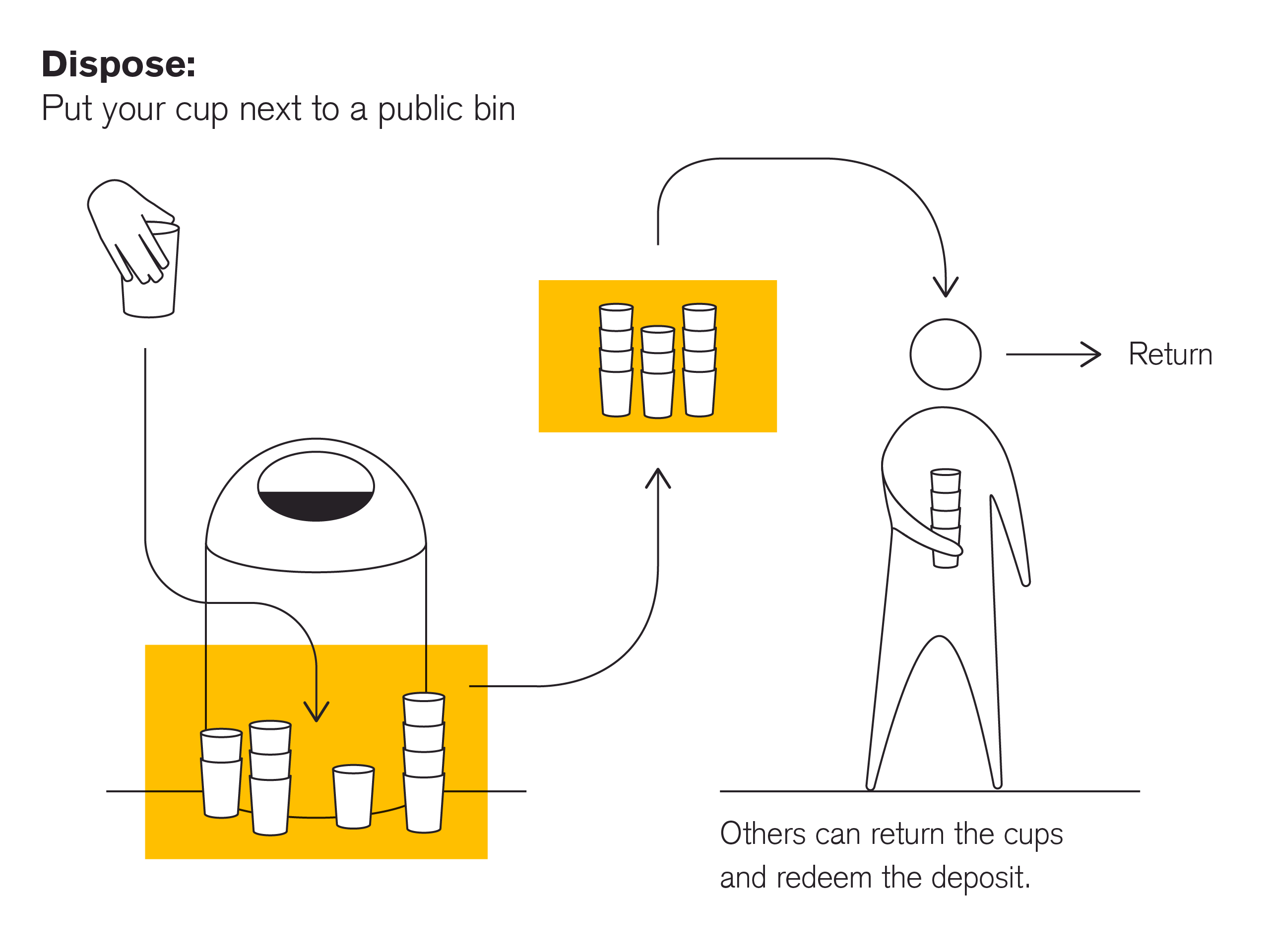

Customers benefit from an improved drinking experience from the disposable and reusable cups while being as convenient as before. Low-income people will be able to gain some money by collecting and returning cups, doing the environment a favor in the process.

Businesses can improve their public standing by joining into the system and benefit from a cleaner surrounding area around their shops. Aid organizations and local initiatives will have more funding available through the donated deposits.

Implementation and Transition

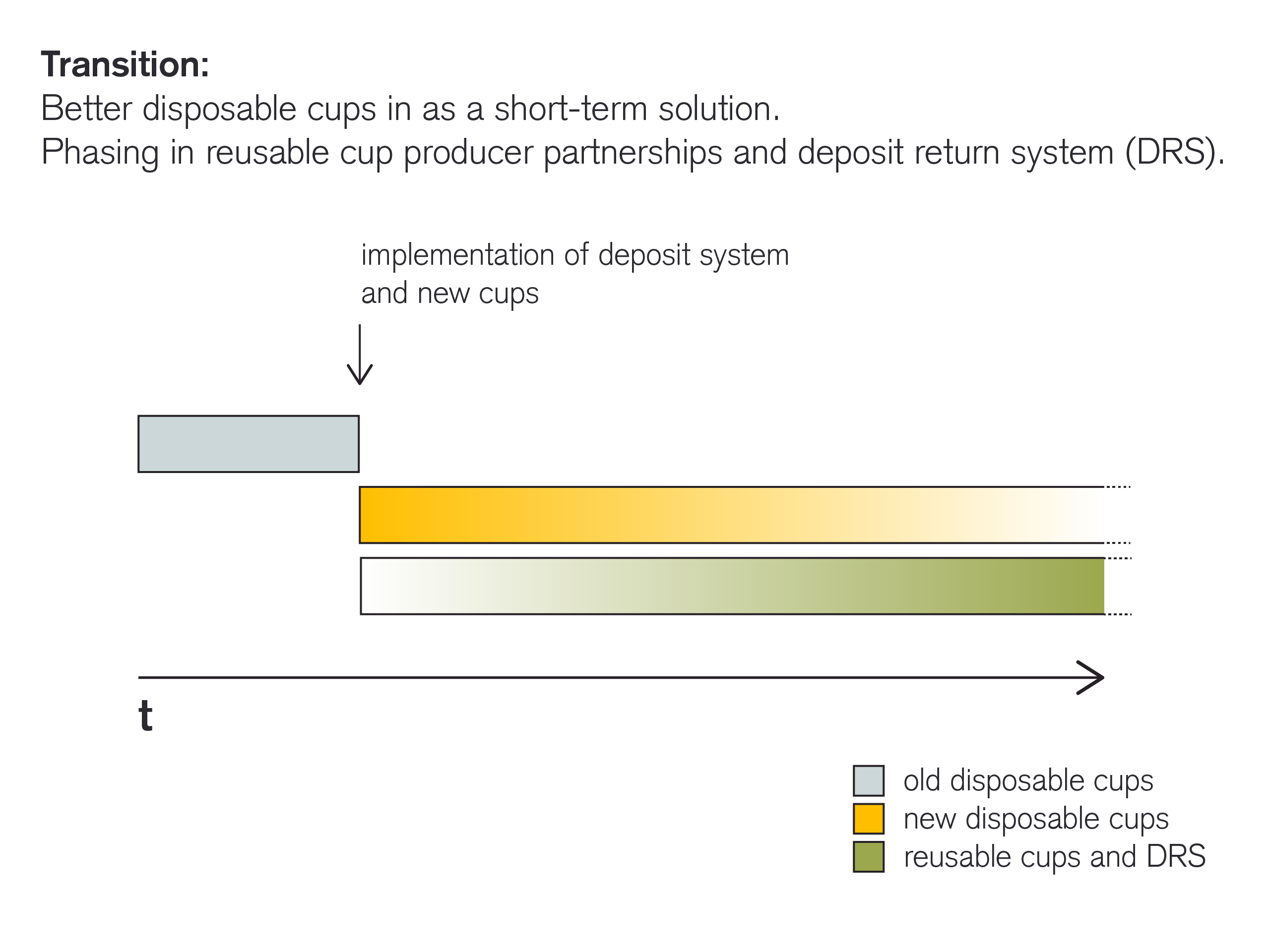

Since a quickly realizable solution is required, we have developed the following strategy:

A new deposit system will be launched at the same time as the new disposable cup, which can be used immediately and is similar to the handling of the user as usual disposable cups.

Thus, the user is forced to choose the more environmentally friendly variant but hardly experiences any change. Over time, more and more stores will be able to implement reusable cups and DRS. The user still has the option of using disposable cups, but over time, he or she will choose the reusable cup more frequently.

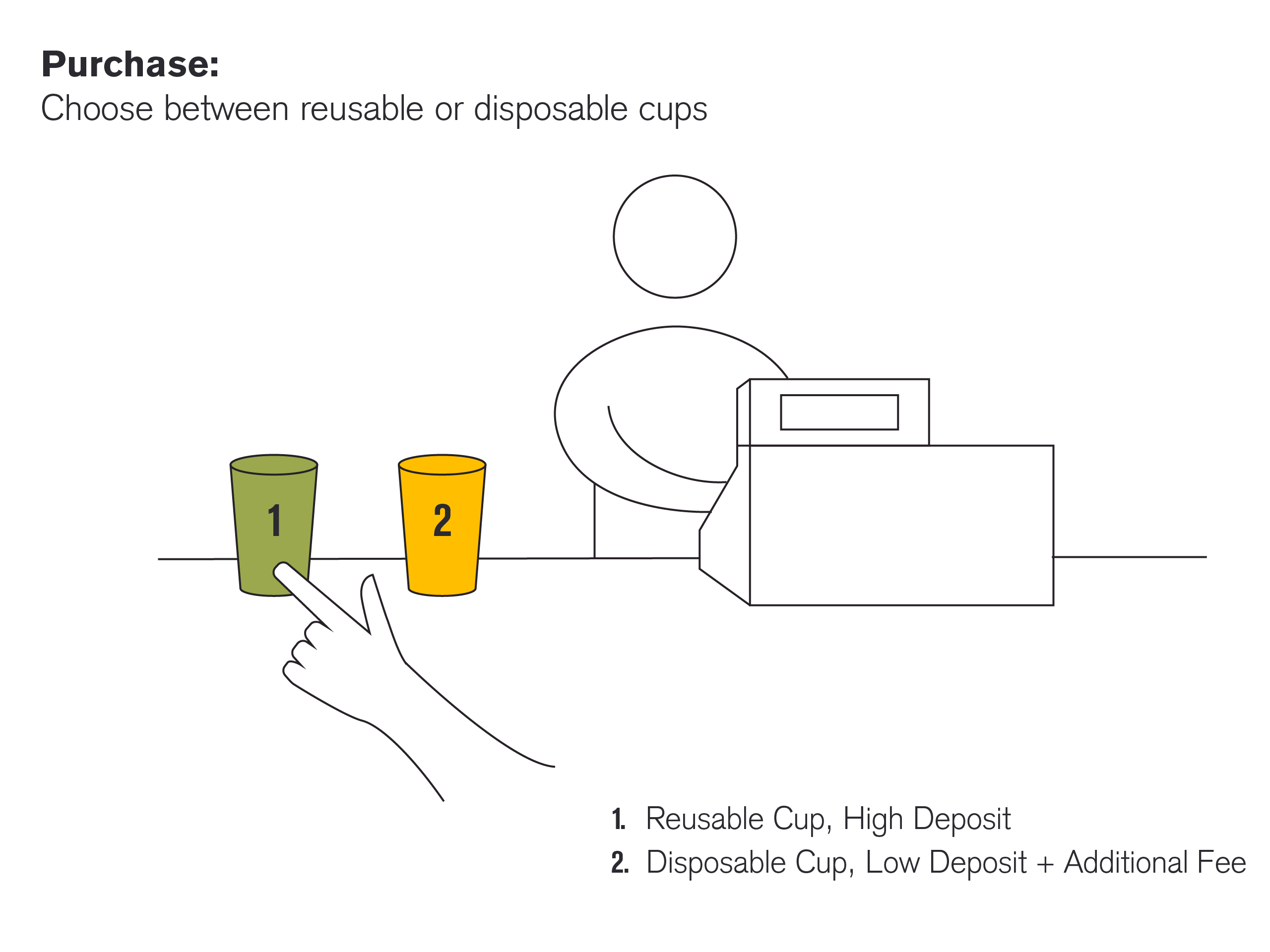

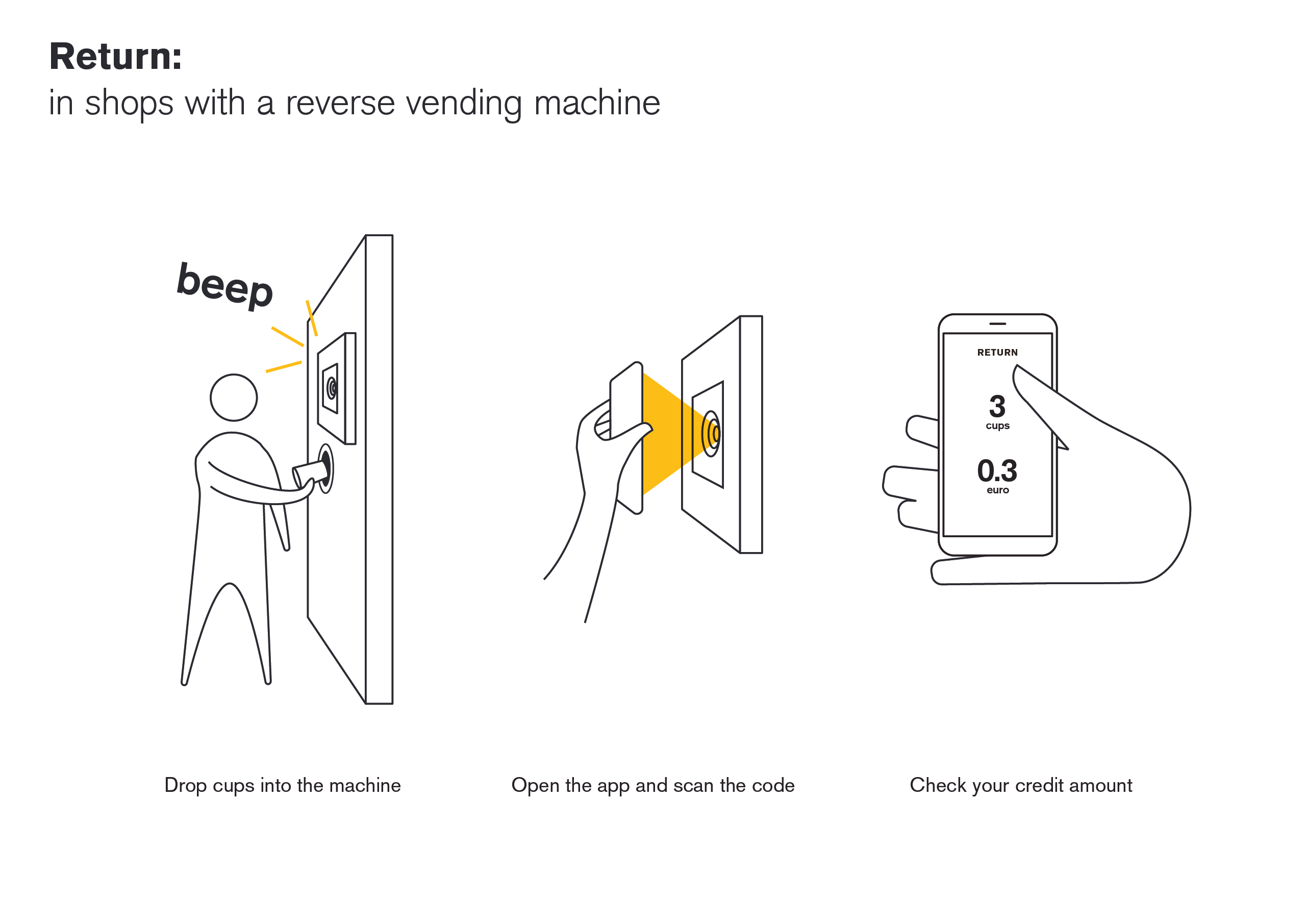

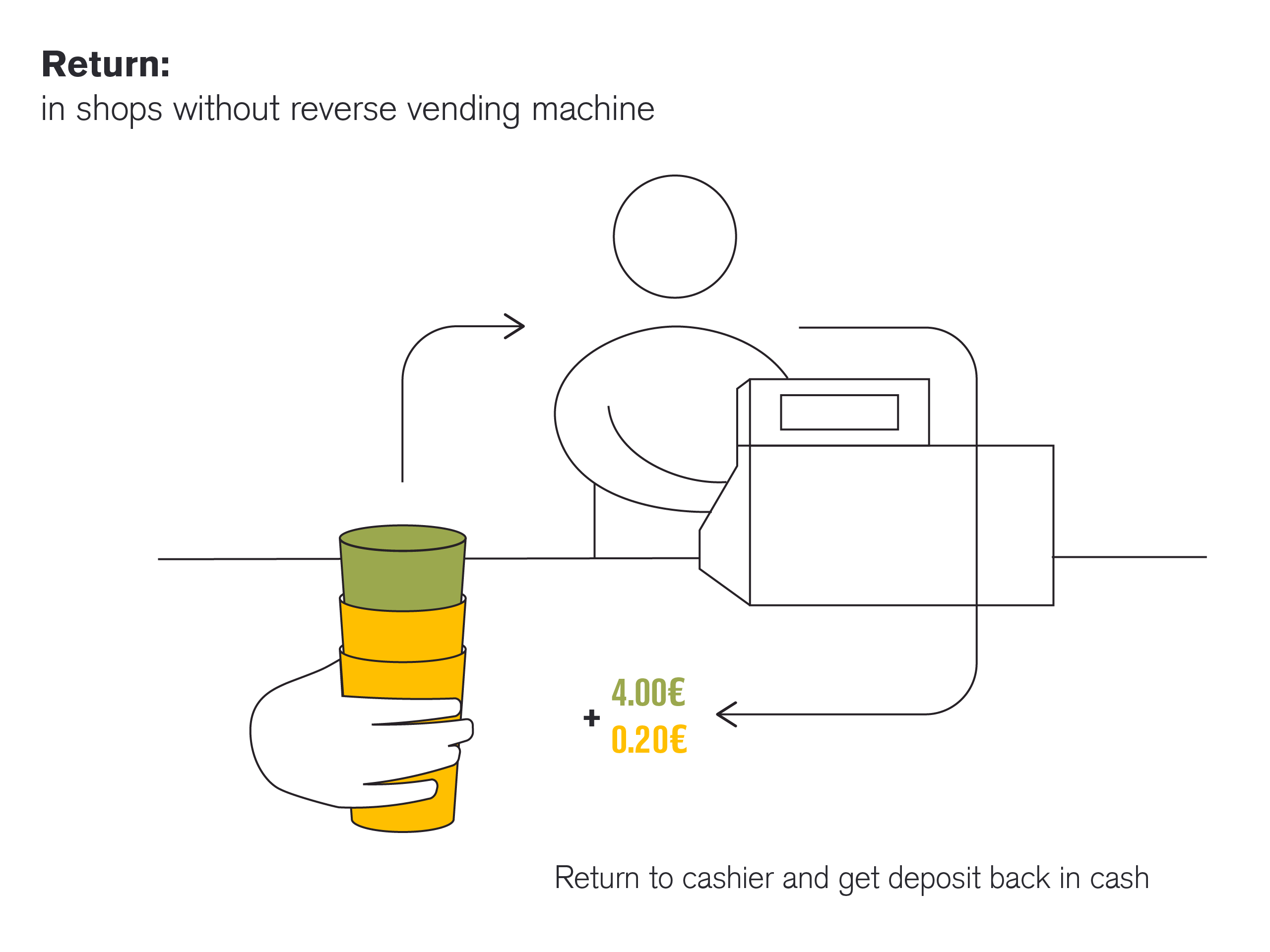

GoodCup Deposit Return System (DRS)

The GoodCup Return System describes a return-to-retail collection model. The used cups are taken back and cleaned, followed by the redistribution of the reusable cups to the stores.

The system provides monetary incentive for customers to return their used cups and gives the opportunity for others to collect and return cups for income – which significantly improves the recycling rate. Customers are being educated about the environmental impact to encourage behavior change.

Communication Strategy

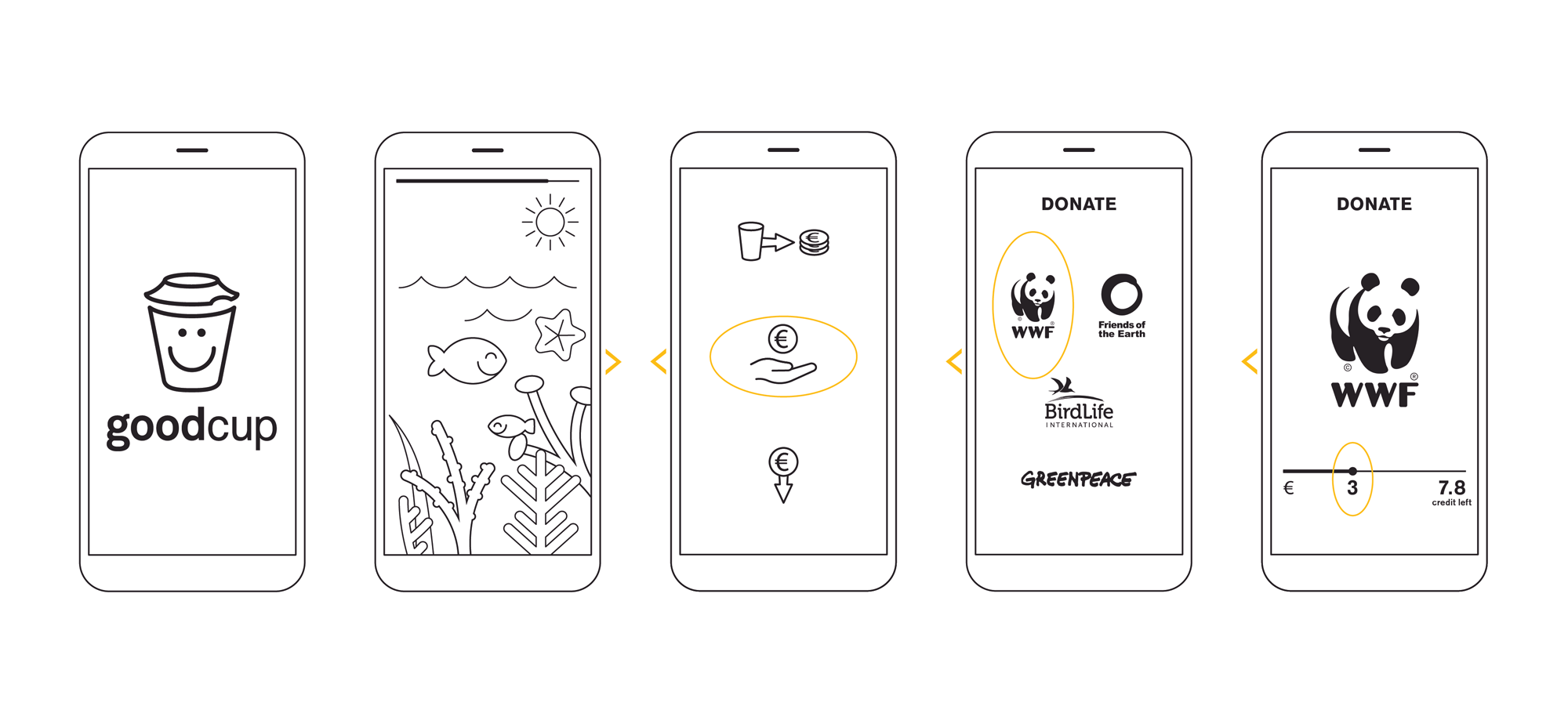

Through the good cup app, social media, our website and strong in-store communication we will educate customers about the impacts of using disposable cups and collect feedback about the new cup and the DRS. The app lets customers track their individual impact by the number of cups they’ve returned and the energy and material saving they achieved.

The disposable cup

Materials

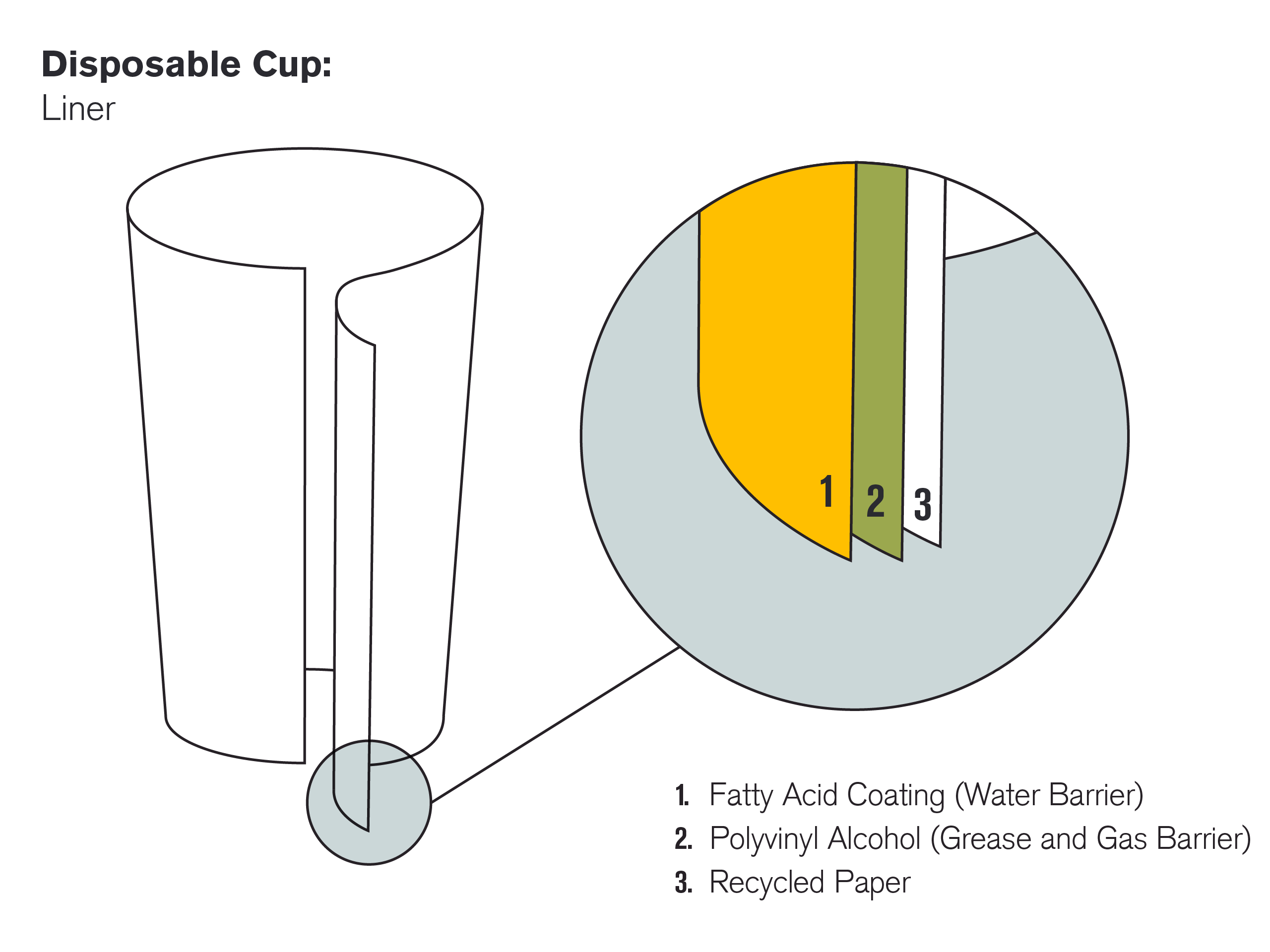

The cup and the lid itself are made of fresh fiber paper, the cup insulation is made of recycled paper. We use soy-based inks for the printings on the cup, which are environmentally friendly. The coating for cup and lid is composed of polyvinyl alcohol (PVOH) and fatty acid chlorides. The water soluble PVOH- and the fatty acid coating is washed out during the drinking process. This makes the goodcup (cup and lid) fully recyclable and repulpable, as opposed to the polyethylene-coated cups.

Sourcing

The paper content of the fiber cup will consist of approximately 30 % recycled paper (insulation layer) and 70% fresh fiber material that will be bought from paper mills as close to the production facilities of the cup as possible. All of the paper should be FSC certified to ensure that the forests we are sourcing from have been managed properly.

The components used in the coating process (PVOH, fatty acid chlorides) can be sourced from the closest chemical supplier or imported if there is no supplier nearby. PVOH demand is anticipated to grow over the next decade, therefore it is expected to become cheaper and more available as the number of suppliers increases as well.

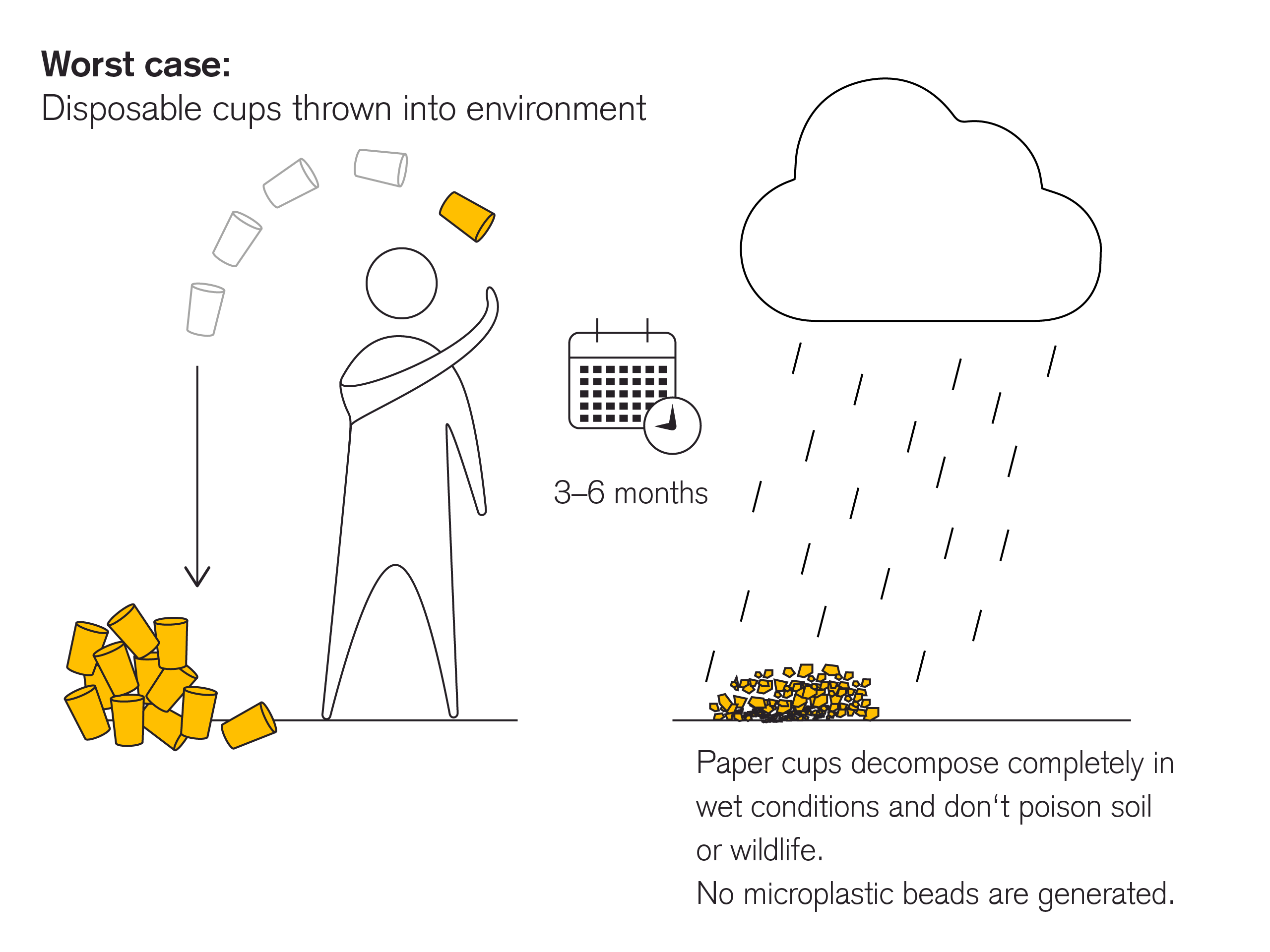

Recoverability

All of the materials can be recovered via classical paper recycling.

Additionally, by adapting consumers gradually to the deposit system and making them an essential part of the recovery system, many of the cups that would have ended up in landfills are instead returned to the shops, where they can be sent to recycling providers in batches.

Performance

The GoodCup design stays close to the stablished disposable cup design, so misuse is reduced and it’s easy for customers to use the cup and enjoy their beverage. Compared to the current cups, the drinking experience is improved, because the mouth doesn’t come into contact with hard plastic materials.

The polyvinyl alcohol (PVOH/PVA) used as the aroma- and gas barrier-coating has been studied extensively on humans and is contained in many cosmetic and medicinal products. It is therefore safe to say, that PVOH is safe for human consumption and not harmful to flora or fauna.

Reflection

This project was an exciting challenge tied to a super important topic. To understand the motivations of disposable cup users for this, it was very important to do research in a wide variety of cafés in Hamburg. I was very happy with our holistic concept, which includes both a transitional solution and an ideal deposit solution. Felix and I led a workshop for the whole team, which was a new experience for me – I realized how important the preparation and post processing of workshops is to generate a great outcome.

My contribution

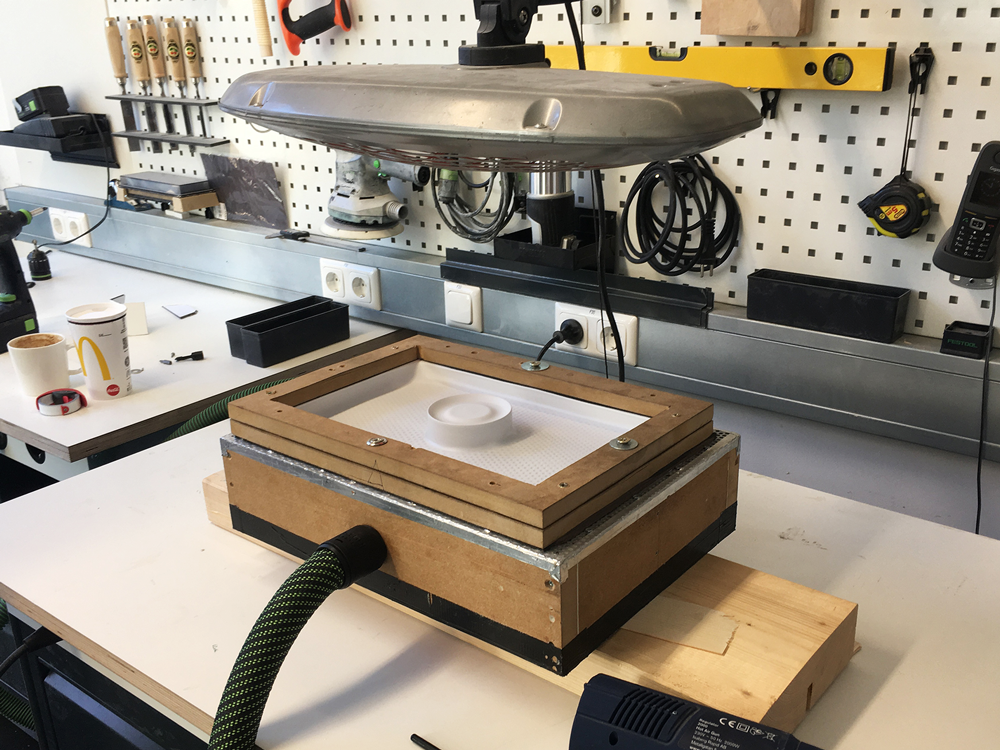

Mainly Felix, at this time another intern at design for human nature, and I worked on the project. We had support in the form of feedback and the workshop with the whole ‘dfhn’ team. My responsibilities included research, conception, the system development, sketches, CAD and model making.